E-mail:sales@tmcut.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

TE-1725

TIMING

Max Cutting Height | 6cm / 9cm (after vac-sorb) |

Cutting Window | length (no limitation) |

width (no wider than the fabric width) | |

Working Width (Y) | 1700mm /2000mm/2200mm |

Normal Working Length (X) | 2500mm/3300mm optional |

Electricity | Three phase 380V, 30KVA,50~60Hz |

Power Consumption | 18KW max |

CAD&CAM Connect way | Ethernet communication / USB Flash memory |

Max speed of blade working | 6000rpm/min |

Compressed Air | 0.55Mpa 160L/min |

Cutting Speed | max.60000mm/min |

Acceleration | 0.8~1g (N/ Kg) |

Noise Level | < 75 dbA |

1. Phone Support for solving problems.

2. Remote Support provided by our consultants through the Internet by means of the Team Viewer program.

3. ON-Site Support in abroad.

4. Sample Free Testing. We offer samples free testing according to clients requirements on processing before selling. So that we offer you the best machine and solutions.

5. Free Training. We provide clients with relative free training on operation and maintenancotally controlling it.

1. Are you trading company or manufacturer?

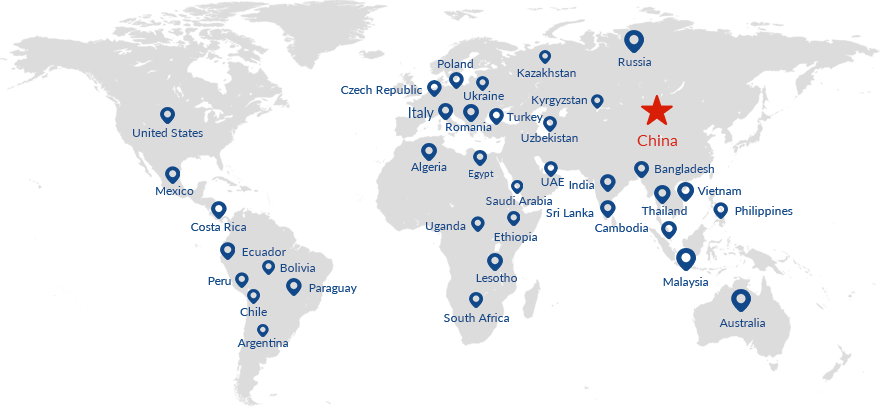

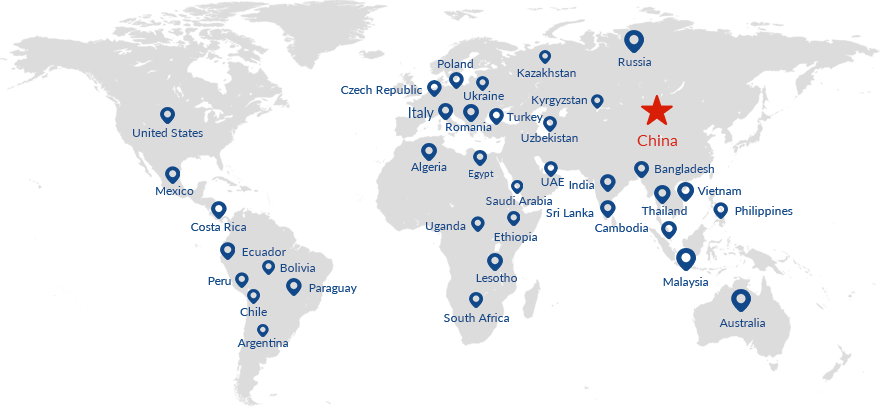

We are manufacturer. Our factory is located in Wuhan city, Hubei province, China.

2. How many years does your factory work on the cutter?

We have been working on motion control system sine 2004. Startrd auto cutter development and research in 2012.

3. What languages are supported?

English/ Vietnamese/ Romanian and Chinese in menu.

If other language in need, contact your sales window for details.

4. What about warranty?

12 months from the date of installation.

5. Should I prepare a computer?

One computer (DELL/ LENOVO optional) in pack, no need to pay extra.

6. How thick your machine can cut?

Up to 9 cm after compressed by vacuum.

There are 3cm, 5cm, 7cm, 9cm models available, choose the right model according to material graphic maker nesting/ yield and factory plan.

7. Will you send engineer for installation and training at overseas factory? What's the cost?

Yes, we will send engineer(s) for the cutter installation and training. No labor cost, but round tickets and accommodarions should be by the customer.

Max Cutting Height | 6cm / 9cm (after vac-sorb) |

Cutting Window | length (no limitation) |

width (no wider than the fabric width) | |

Working Width (Y) | 1700mm /2000mm/2200mm |

Normal Working Length (X) | 2500mm/3300mm optional |

Electricity | Three phase 380V, 30KVA,50~60Hz |

Power Consumption | 18KW max |

CAD&CAM Connect way | Ethernet communication / USB Flash memory |

Max speed of blade working | 6000rpm/min |

Compressed Air | 0.55Mpa 160L/min |

Cutting Speed | max.60000mm/min |

Acceleration | 0.8~1g (N/ Kg) |

Noise Level | < 75 dbA |

1. Phone Support for solving problems.

2. Remote Support provided by our consultants through the Internet by means of the Team Viewer program.

3. ON-Site Support in abroad.

4. Sample Free Testing. We offer samples free testing according to clients requirements on processing before selling. So that we offer you the best machine and solutions.

5. Free Training. We provide clients with relative free training on operation and maintenancotally controlling it.

1. Are you trading company or manufacturer?

We are manufacturer. Our factory is located in Wuhan city, Hubei province, China.

2. How many years does your factory work on the cutter?

We have been working on motion control system sine 2004. Startrd auto cutter development and research in 2012.

3. What languages are supported?

English/ Vietnamese/ Romanian and Chinese in menu.

If other language in need, contact your sales window for details.

4. What about warranty?

12 months from the date of installation.

5. Should I prepare a computer?

One computer (DELL/ LENOVO optional) in pack, no need to pay extra.

6. How thick your machine can cut?

Up to 9 cm after compressed by vacuum.

There are 3cm, 5cm, 7cm, 9cm models available, choose the right model according to material graphic maker nesting/ yield and factory plan.

7. Will you send engineer for installation and training at overseas factory? What's the cost?

Yes, we will send engineer(s) for the cutter installation and training. No labor cost, but round tickets and accommodarions should be by the customer.